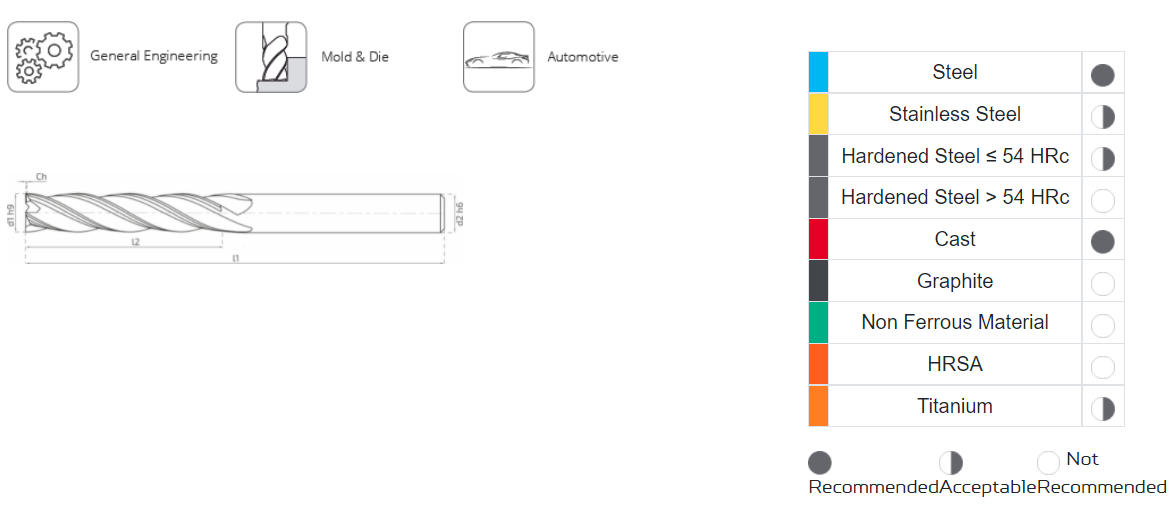

| STOK | KOD | d1h10 | l2 | l1 | d2h6 | ch |

|---|---|---|---|---|---|---|

| * | FXUF30 | 3 | 15 | 75 | 3 | 0.1 |

| * | FXUF40 | 4 | 20 | 75 | 4 | 0.1 |

| * | FXUF41 | 4 | 31 | 100 | 4 | 0.1 |

| * | FXUF50 | 5 | 20 | 75 | 5 | 0.1 |

| * | FXUF60 | 6 | 25 | 75 | 6 | 0.1 |

| * | FXUF61 | 6 | 40 | 100 | 6 | 0.1 |

| * | FXUF80 | 8 | 31 | 75 | 8 | 0.1 |

| * | FXUF81 | 8 | 40 | 100 | 8 | 0.1 |

| * | FXUF100 | 10 | 55 | 110 | 10 | 0.1 |

| * | FXUF120 | 12 | 55 | 110 | 12 | 0.15 |

| FXUF140 | 14 | 75 | 150 | 14 | 0.15 | |

| FXUF160 | 16 | 75 | 150 | 16 | 0.1 | |

| FXUF180 | 18 | 75 | 150 | 18 | 0.1 | |

| FXUF200 | 20 | 75 | 150 | 20 | 0.15 |

| Material | Slotting ap=0.5 - 0.1Ø Vc (m/min) | Shoulder Milling ap=1.5Ø / ae=0.30 - 0.20Ø Vc (m/min) | Finish Milling ap=1.5Ø / ae=0.20 - 0.10Ø Vc (m/min) |

|---|---|---|---|

|

|

|

|

|

| Unalloyed steel | 95-*125 | 180-210 | 210-230 |

| Steel | 90-120 | 180-210 | 210-230 |

| Tempered steel | 80-110 | 160-190 | 190-120 |

| Cold work tool steel | 70-90 | 150-180 | 170-200 |

| Hot work tool steel | 60-80 | 140-170 | 160-190 |

| Gray cast | 100-130 | 250-280 | 280-330 |

| Alloyed cast | 70-100 | 150-190 | 190-240 |

| Precision cast | 60-90 | 130-160 | 160-210 |

| Ø | ap=0.050Ø | ae=0.10Ø | ae=0.30Ø | ae=0.20Ø | ae=0.15Ø | ae=0.10Ø |

|---|---|---|---|---|---|---|

| 3 | 0.005 | 0.006 | 0.031 | 0.036 | 0.038 | 0.04 |

| 4 | 0.008 | 0.011 | 0.038 | 0.042 | 0.044 | 0.046 |

| 5 | 0.013 | 0.017 | 0.041 | 0.043 | 0.045 | 0.047 |

| 6 | 0.016 | 0.022 | 0.048 | 0.052 | 0.054 | 0.056 |

| 8 | 0.021 | 0.027 | 0.054 | 0.058 | 0.061 | 0.064 |

| 10 | 0.029 | 0.035 | 0.062 | 0.066 | 0.069 | 0.072 |

| 12 | 0.038 | 0.043 | 0.067 | 0.072 | 0.075 | 0.079 |

| 14 | 0.047 | 0.052 | 0.072 | 0.077 | 0.08 | 0.083 |

| 16 | 0.056 | 0.063 | 0.076 | 0.081 | 0.086 | 0.09 |

| 18 | 0.068 | 0.073 | 0.079 | 0.085 | 0.089 | 0.095 |

| 20 | 0.078 | 0.084 | 0.084 | 0.092 | 0.097 | 0.098 |

| 25 | 0.105 | 0.11 | 0.088 | 0.1 | 0.11 | 0.11 |

Türkçe

Türkçe