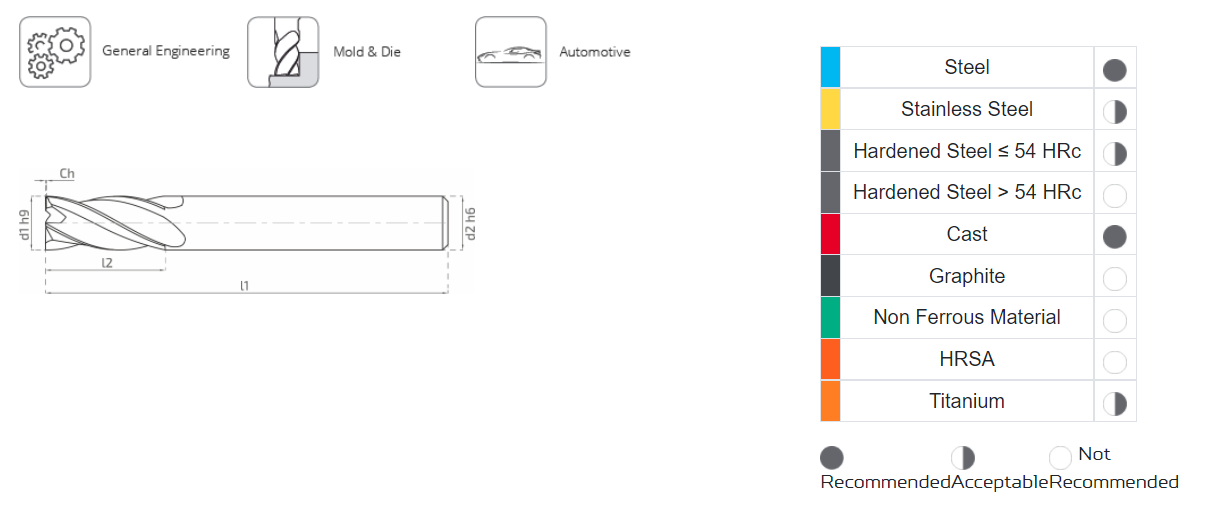

| STOK | KOD | d1h10 | l2 | l1 | d2h6 | R | Z |

|---|---|---|---|---|---|---|---|

| * | FXSF30 | 3 | 6 | 51 | 3 | 0.5 | 4 |

| * | FXSF31 | 3 | 6 | 51 | 3 | 1 | 4 |

| * | FXSF40 | 4 | 8 | 51 | 4 | 0.5 | 4 |

| * | FXSF41 | 4 | 8 | 51 | 4 | 1 | 4 |

| * | FXSF50 | 5 | 11 | 51 | 5 | 0.5 | 4 |

| * | FXSF51 | 5 | 11 | 51 | 5 | 1 | 4 |

| * | FXSF60 | 6 | 12 | 58 | 6 | 0.5 | 4 |

| * | FXSF61 | 6 | 12 | 58 | 6 | 1 | 4 |

| * | FXSF80 | 8 | 20 | 64 | 8 | 0.5 | 4 |

| * | FXSF81 | 8 | 20 | 64 | 8 | 1 | 4 |

| * | FXSF100 | 10 | 21 | 73 | 10 | 0.5 | 4 |

| * | FXSF101 | 10 | 21 | 73 | 10 | 1 | 4 |

| * | FXSF120 | 12 | 25 | 82 | 12 | 0.5 | 4 |

| * | FXSF121 | 12 | 25 | 82 | 12 | 1 | 4 |

| FXSF140 | 14 | 30 | 82 | 14 | 0.5 | 4 | |

| FXSF141 | 14 | 30 | 82 | 14 | 1 | 4 | |

| FXSF160 | 16 | 35 | 93 | 16 | 0.5 | 4 | |

| FXSF161 | 16 | 35 | 93 | 16 | 1 | 4 |

| Material | Slotting ap=0,5xØ Vc (m/min) | Shoulder Milling ae=0,5xØ ap=1xØ Vc (m/min) | Shoulder Milling ae=0,1xØ ap=1,5xØ Vc (m/min) |

|---|---|---|---|

|

|

|

|

|

| Unalloyed steel | 145 | 175 | 290 |

| Steel | 110 | 135 | 200 |

| Tempered steel | 105 | 100 | 170 |

| Cold work tool steel | 80 | 90 | 130 |

| Hot work tool steel | 80 | 90 | 130 |

| AISI 304 - 416 - 420 | 65 | 80 | 150 |

| AISI 316 - 440 | 60 | 75 | 120 |

| 17-4 PH 15-5 PH | 60 | 75 | 120 |

| Chrome-Cobalt alloy | 50 | 60 | 80 |

| Duplex F51 | 55 | 70 | 90 |

| Super duplex F55 | 55 | 70 | 90 |

| Gray cast | 140 | 165 | 150 |

| Alloyed cast | 130 | 150 | 200 |

| Precision cast | 125 | 145 | 155 |

| Iron-based superalloys | 30 | 40 | 50 |

| Nickel-based superalloys | 30 | 40 | 60 |

| Titanium-based superalloys | 40 | 50 | 100 |

| Ø | ap=1.5Ø | ap=1Ø | ap=0.50Ø | ae=0.35Ø | ae=0.30Ø |

|---|---|---|---|---|---|

| 3 | 0.007 | 0.032 | 0.037 | 0.039 | 0.041 |

| 4 | 0.012 | 0.039 | 0.043 | 0.045 | 0.047 |

| 5 | 0.018 | 0.042 | 0.044 | 0.046 | 0.048 |

| 6 | 0.023 | 0.049 | 0.053 | 0.055 | 0.057 |

| 8 | 0.028 | 0.056 | 0.06 | 0.063 | 0.066 |

| 10 | 0.036 | 0.064 | 0.068 | 0.071 | 0.074 |

| 12 | 0.045 | 0.069 | 0.074 | 0.077 | 0.08 |

| 14 | 0.054 | 0.074 | 0.079 | 0.083 | 0.086 |

| 16 | 0.065 | 0.079 | 0.084 | 0.089 | 0.093 |

| 18 | 0.076 | 0.082 | 0.088 | 0.093 | 0.097 |

| 20 | 0.087 | 0.087 | 0.095 | 0.1 | 0.105 |

| 25 | 0.115 | 0.092 | 0.105 | 0.11 | 0.119 |

Türkçe

Türkçe