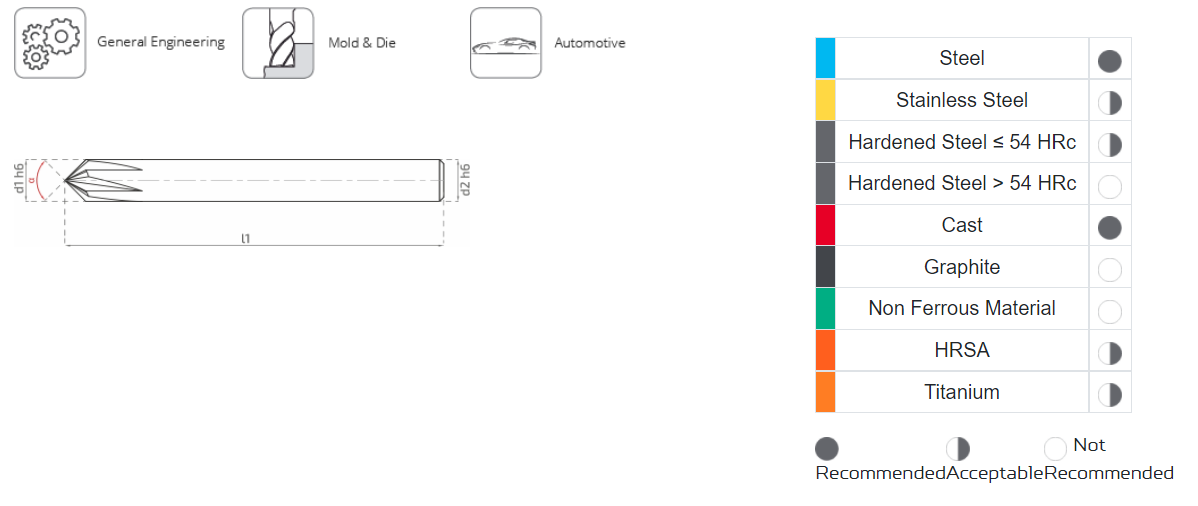

| STOK | KOD | d1h6 | l2 | l1 | d2h6 | α (°) | Z |

|---|---|---|---|---|---|---|---|

| FXMCX40 | 4 | 9 | 51 | 6 | 90 | 4 | |

| FXMCX50 | 5 | 12 | 58 | 6 | 90 | 4 | |

| FXMCX60 | 6 | 15 | 58 | 6 | 90 | 4 | |

| FXMCX80 | 8 | 15 | 64 | 8 | 90 | 5 | |

| FXMCX100 | 10 | 21 | 73 | 10 | 90 | 6 | |

| FXMCX120 | 12 | 25 | 82 | 12 | 90 | 6 |

| Material | Quarter Circle Vc (m/min) |

|---|---|

|

|

|

| Unalloyed steel | 280-320 |

| Steel | 220-250 |

| Tempered steel | 190-220 |

| Cold work tool steel | 100-130 |

| Hot work tool steel | 100-130 |

| AISI 304 - 416 - 420 | 80-110 |

| AISI 316 - 440 | 80-110 |

| 17-4 PH 15-5 PH | 60-90 |

| Chrome-Cobalt alloy | 60-90 |

| Duplex F51 | 50-70 |

| Super duplex F55 | 50-70 |

| Gray cast | 200-240 |

| Alloyed cast | 200-240 |

| Precision cast | 180-215 |

| Aluminium alloys | 230-370 |

| Coper alloys | 650-680 |

| Iron-based superalloys | 40-50 |

| Nickel-based superalloys | 40-50 |

| Titanium-based superalloys | 70-90 |

| Ø | Ø | ||

|---|---|---|---|

| 4.5 | 0.005 | 3.5 | 0.03 |

| 7.5 | 0.005 | 4.5 | 0.035 |

| 10.5 | 0.005 | 5 | 0.038 |

| 13.5 | 0.005 | 5.5 | 0.041 |

| 16.5 | 0.005 | 6 | 0.044 |

| 19.5 | 0.005 | 8 | 0.05 |

| 22.5 | 0.005 | ||

| 25.5 | 0.005 | ||

| 28.5 | 0.005 |

Türkçe

Türkçe