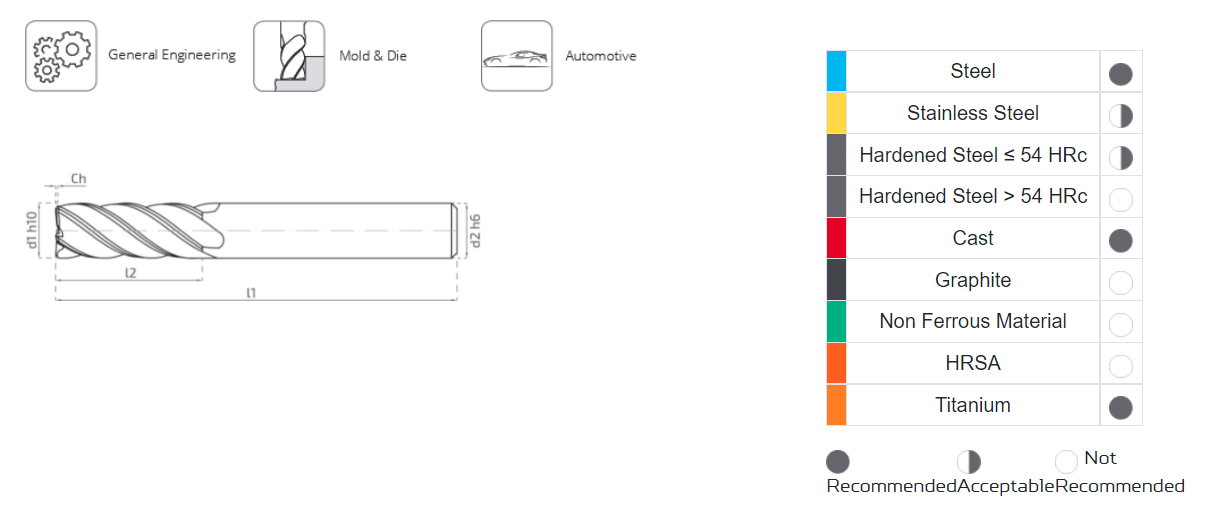

| STOK | KOD | d1h10 | l2 | l1 | d2h6 | Ch | Z |

|---|---|---|---|---|---|---|---|

| 6 | 15 | 58 | 6 | 0.1 | 6 | ||

| 8 | 19 | 64 | 8 | 0.1 | 6 | ||

| 10 | 22 | 73 | 10 | 0.1 | 6 | ||

| 12 | 26 | 82 | 12 | 0.1 | 6 | ||

| 14 | 31 | 82 | 14 | 0.15 | 6 | ||

| 16 | 32 | 93 | 16 | 0.15 | 6 | ||

| 18 | 32 | 93 | 18 | 0.15 | 8 | ||

| 20 | 38 | 105 | 20 | 0.15 | 8 | ||

| STOK | KOD | d1h10 | l2 | l1 | d2h6 | Ch | Z |

|---|---|---|---|---|---|---|---|

| F4710U60 | 6 | 30 | 80 | 6 | 0.1 | 6 | |

| F4710U80 | 8 | 40 | 90 | 8 | 0.1 | 6 | |

| F4710U100 | 10 | 45 | 100 | 10 | 0.1 | 6 | |

| F4710U120 | 12 | 55 | 110 | 12 | 0.1 | 6 | |

| F4710U140 | 14 | 60 | 110 | 14 | 0.15 | 6 | |

| F4710U160 | 16 | 70 | 125 | 16 | 0.15 | 6 | |

| F4710U180 | 18 | 70 | 140 | 18 | 0.15 | 8 | |

| F4710U200 | 20 | 75 | 150 | 20 | 0.15 | 8 |

| Malzeme | Shoulder Milling | Shoulder Milling |

|---|---|---|

|

|

|

|

| ap=2.0Ø / ae=0.25Ø | ap=2.0Ø / ae=0.20- 0.10Ø | |

| Vc (m/min) | Vc (m/min) | |

| Unalloyed steel | 100-140 | 140-170 |

| Steel | 80-110 | 110-140 |

| Tempered steel | 80-100 | 105-130 |

| Cold work tool steel | 60-80 | 80-105 |

| Hot work tool steel | 60-80 | 80-105 |

| AISI 304 - 416 - 420 | 40-60 | 55-80 |

| AISI 316 - 440 | 40-60 | 55-80 |

| 17-4 PH 15-5 PH | 40-60 | 55-80 |

| Chrome-Cobalt alloy | 40-60 | 55-80 |

| Duplex F51 | 40-60 | 55-80 |

| Super duplex F55 | 40-60 | 55-80 |

| Gray cast | 80-110 | 110-140 |

| Alloyed cast | 80-100 | 105-130 |

| Precision cast | 80-100 | 105-130 |

| Titanium | 40-50 | 50-70 |

| Titanium alloys | 40-50 | 50-70 |

| Ø | ae=0.25Ø | ae=0.20Ø | ae=0.10Ø |

|---|---|---|---|

| 6 | 0.028 | 0.03 | 0.024 |

| 8 | 0.046 | 0.051 | 0.045 |

| 10 | 0.054 | 0.059 | 0.051 |

| 12 | 0.06 | 0.066 | 0.057 |

| 14 | 0.064 | 0.074 | 0.063 |

| 16 | 0.073 | 0.079 | 0.069 |

| 18 | 0.078 | 0.086 | 0.074 |

| 20 | 0.085 | 0.092 | 0.08 |

Türkçe

Türkçe