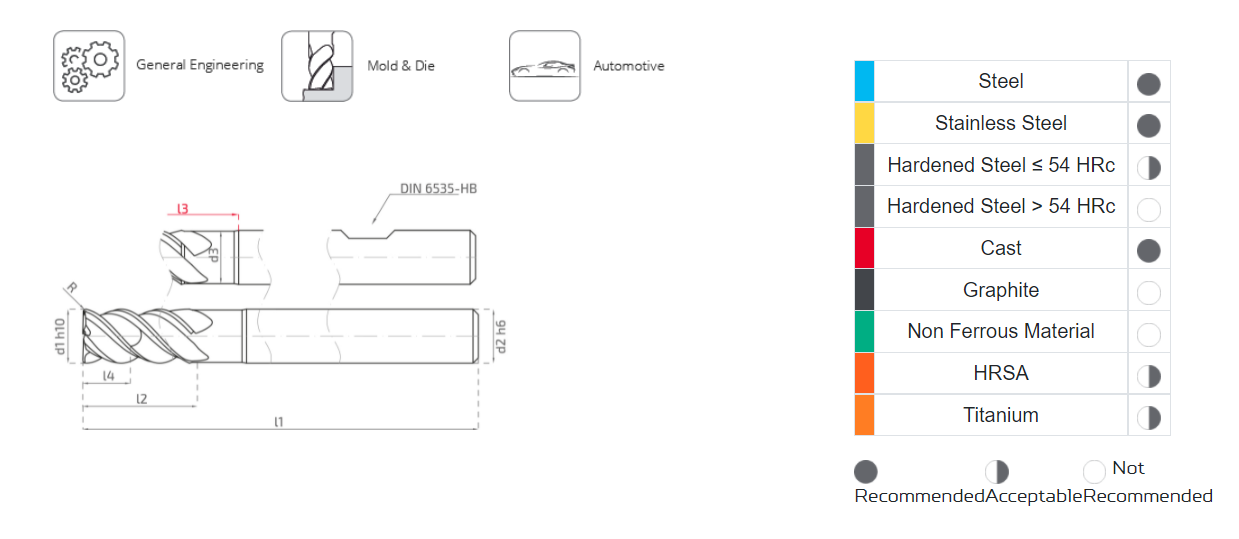

| STOK | KOD | d1h10 | l4 | l2 | l3 | d3 | l1 | d2h6 | R | Z |

|---|---|---|---|---|---|---|---|---|---|---|

| * | F431030 | 3 | 5 | 11 | 20 | 2.8 | 58 | 6 | 0.2 | 3 |

| F431031 | 3 | 5 | 11 | 20 | 2.8 | 58 | 6 | 0.2 | 4 | |

| * | F431040 | 4 | 6 | 12 | 21 | 3.8 | 58 | 6 | 0.2 | 3 |

| * | F431041 | 4 | 6 | 12 | 21 | 3.8 | 58 | 6 | 0.2 | 4 |

| * | F431050 | 5 | 6 | 13 | 17 | 4.8 | 58 | 6 | 0.2 | 4 |

| * | 6 | 13 | 17 | 4.8 | 58 | 6 | 0.5 | 4 | ||

| * | 8 | 15 | 20 | 5.7 | 58 | 6 | 0.2 | 4 | ||

| * | F431060 | 6 | 8 | 15 | 20 | 5.7 | 58 | 6 | 0.5 | 4 |

| F431070 | 7 | 10 | 21 | 27 | 6.5 | 64 | 8 | 0.2 | 4 | |

| * | F431080 | 8 | 10 | 21 | 28 | 7.7 | 64 | 8 | 0.2 | 4 |

| * | F431081 | 8 | 10 | 21 | 28 | 7.7 | 64 | 8 | 0.5 | 4 |

| F431082 | 8 | 10 | 21 | 28 | 7.7 | 64 | 8 | 1 | 4 | |

| F431083 | 8 | 10 | 21 | 28 | 7.7 | 64 | 8 | 2 | 4 | |

| * | F4310100 | 10 | 12 | 21 | 27 | 9.5 | 73 | 10 | 0.2 | 4 |

| * | F4310101 | 10 | 12 | 21 | 27 | 9.5 | 73 | 10 | 0.5 | 4 |

| F4310102 | 10 | 12 | 21 | 27 | 9.5 | 73 | 10 | 0.8 | 4 | |

| F4310103 | 10 | 12 | 21 | 27 | 9.5 | 73 | 10 | 1 | 4 | |

| F4310104 | 10 | 12 | 21 | 27 | 9.5 | 73 | 10 | 1.5 | 4 | |

| F4310105 | 10 | 12 | 21 | 27 | 9.5 | 73 | 10 | 2 | 4 | |

| F4310106 | 10 | 12 | 21 | 27 | 9.5 | 73 | 10 | 3 | 4 | |

| * | F4310120 | 12 | 16 | 29 | 39 | 11.5 | 82 | 12 | 0.3 | 4 |

| * | F4310121 | 12 | 16 | 29 | 39 | 11.5 | 82 | 12 | 0.5 | 4 |

| F4310122 | 12 | 16 | 29 | 39 | 11.5 | 82 | 12 | 1 | 4 | |

| F4310123 | 12 | 16 | 29 | 39 | 11.5 | 82 | 12 | 1.5 | 4 | |

| F4310124 | 12 | 16 | 29 | 39 | 11.5 | 82 | 12 | 2 | 4 | |

| F4310125 | 12 | 16 | 29 | 39 | 11.5 | 82 | 12 | 3 | 4 | |

| F4310140 | 14 | 13 | 26 | 36 | 13.5 | 82 | 14 | 0 | 4 | |

| * | F4310141 | 14 | 13 | 26 | 36 | 13.5 | 82 | 14 | 0.3 | 4 |

| * | F4310160 | 16 | 21 | 36 | 44 | 15.5 | 93 | 16 | 0.3 | 4 |

| * | F4310161 | 16 | 21 | 36 | 44 | 15.5 | 93 | 16 | 0.5 | 4 |

| F4310162 | 16 | 21 | 36 | 44 | 15.5 | 93 | 16 | 1 | 4 | |

| F4310163 | 16 | 21 | 36 | 44 | 15.5 | 93 | 16 | 1.5 | 4 | |

| * | F4310200 | 20 | 19 | 38 | 54 | 19.5 | 105 | 20 | 0.3 | 4 |

| Material | Slotting | Shoulder Milling | Finish Milling |

|---|---|---|---|

|

|

|

|

|

| ap=1.0Ø | ap=1.5Ø / ae=0.35 - 0.20Ø | ap=1.5Ø / ae=0.20 - 0.10Ø | |

| Vc (m/min) | Vc (m/min) | Vc (m/min) | |

| Unalloyed steel | 100-130 | 130-160 | 150-180 |

| Steel | 100-130 | 130-160 | 150-180 |

| Tempered steel | 80-110 | 110-140 | 130-160 |

| Cold work tool steel | 70-100 | 90-120 | 110-135 |

| Hot work tool steel | 65-95 | 80-110 | 100-125 |

| AISI 304 - 416 - 420 | 20-50 | 30-60 | 50-90 |

| AISI 316 - 440 | 20-50 | 30-60 | 50-90 |

| 17-4 PH 15-5 PH | 20-40 | 30-50 | 40-70 |

| Chrome-Cobalt alloy | 20-40 | 30-50 | 40-70 |

| Gray cast | 70-100 | 100-130 | 120-150 |

| Alloyed cast | 70-100 | 90-120 | 110-145 |

| Precision cast | 50-80 | 70-100 | 90-115 |

| < 54 HRC | 25-35 | 35-40 | 35-45 |

| HRSA hastelloy | 30-50 | 40-60 | 50-70 |

| HRSA inconel 625 | 30-50 | 40-60 | 50-70 |

| HRSA inconel 718 | 30-50 | 40-60 | 50-70 |

| HRSA nimonic | 30-50 | 40-60 | 50-70 |

| Titanium | 30-50 | 70-90 | 80-90 |

| Titanium alloys | 30-50 | 70-90 | 80-90 |

| Ø | ap=1Ø | ap=1.50Ø | ae=0.35Ø | ae=0.30Ø | ae=0.25Ø | ae=0.20Ø | ae=0.15Ø | ae=0.10Ø |

|---|---|---|---|---|---|---|---|---|

| 3 | 0.003 | 0.004 | 0.01 | 0.012 | 0.013 | 0.015 | 0.016 | 0.017 |

| 4 | 0.005 | 0.005 | 0.012 | 0.015 | 0.019 | 0.02 | 0.022 | 0.026 |

| 5 | 0.006 | 0.007 | 0.015 | 0.018 | 0.022 | 0.027 | 0.03 | 0.035 |

| 6 | 0.007 | 0.009 | 0.017 | 0.02 | 0.023 | 0.028 | 0.031 | 0.036 |

| 8 | 0.011 | 0.014 | 0.019 | 0.022 | 0.025 | 0.029 | 0.032 | 0.037 |

| 10 | 0.014 | 0.189 | 0.3 | 0.032 | 0.036 | 0.039 | 0.041 | 0.046 |

| 12 | 0.02 | 0.025 | 0.034 | 0.038 | 0.041 | 0.045 | 0.047 | 0.051 |

| 14 | 0.025 | 0.031 | 0.04 | 0.045 | 0.05 | 0.056 | 0.061 | 0.066 |

| 16 | 0.031 | 0.038 | 0.05 | 0.056 | 0.062 | 0.068 | 0.073 | 0.078 |

| 20 | 0.046 | 0.054 | 0.07 | 0.076 | 0.084 | 0.09 | 0.096 | 0.011 |

Türkçe

Türkçe