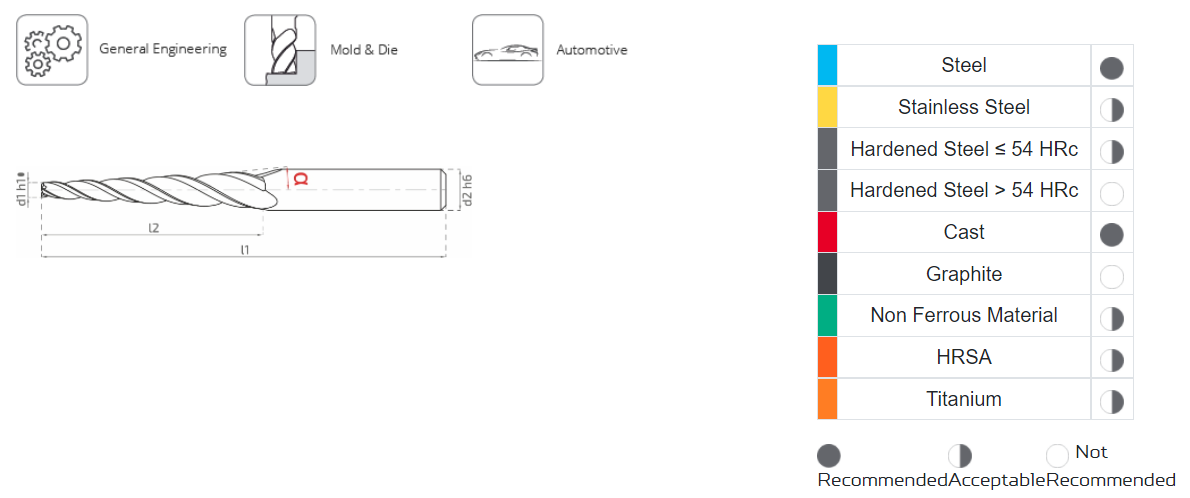

| STOK | KOD | d1h10 | l2 | l1 | d2h6 | α |

|---|---|---|---|---|---|---|

| * | FXKSF20 | 2 | 35 | 64 | 4 | 1,5 ° |

| * | FXKSF25 | 2.5 | 30 | 64 | 4 | 1,5° |

| * | FXKSF40 | 4 | 33 | 75 | 6 | 1,7 ° |

| FXKSF21 | 2 | 38 | 75 | 6 | 2 ° | |

| FXKSF26 | 2.5 | 43 | 82 | 6 | 2 ° | |

| FXKSF27 | 2.5 | 30 | 82 | 8 | 2 ° | |

| FXKSF30 | 3 | 43 | 82 | 6 | 2 ° | |

| * | FXKSF31 | 3 | 40 | 82 | 8 | 2 ° |

| FXKSF41 | 4 | 35 | 75 | 8 | 2 ° | |

| FXKSF32 | 3 | 40 | 82 | 6 | 2,1 ° | |

| FXKSF28 | 2.5 | 42 | 82 | 6 | 2,2 ° | |

| * | FXKSF22 | 2 | 50 | 82 | 6 | 2,3 ° |

| * | FXKSF28 | 2.8 | 33 | 64 | 6 | 2,8 ° |

| * | FXKSF42 | 4 | 40 | 82 | 8 | 2,8 ° |

| * | FXKSF23 | 2 | 38 | 82 | 6 | 3 ° |

| FXKSF29 | 2.5 | 33 | 82 | 6 | 3 ° | |

| * | FXKSF29 | 2.5 | 42 | 82 | 8 | 3° |

| * | FXKSF33 | 3 | 42 | 82 | 8 | 3 ° |

| * | FXKSF34 | 3 | 40 | 110 | 8 | 3 ° |

| FXKSF44 | 4 | 38 | 82 | 8 | 3 ° | |

| FXKSF29 | 2.5 | 31 | 82 | 8 | 5 ° | |

| FXKSF35 | 3 | 28 | 82 | 8 | 5 ° | |

| FXKSF36 | 3 | 40 | 110 | 10 | 5 ° |

| Material | Shoulder Milling ap=0.1Ø / ae=0.30 - 0.20Ø Vc (m/min) |

|---|---|

|

|

|

| Unalloyed steel | 100-130 |

| Steel | 100-130 |

| Tempered steel | 90-120 |

| Cold work tool steel | 80-110 |

| Hot work tool steel | 70-100 |

| AISI 304 - 416 - 420 | 50-80 |

| AISI 316 - 440 | 30-60 |

| 17-4 PH 15-5 PH | 30-60 |

| Duplex F51 | 25-40 |

| Gray cast | 100-130 |

| Coper alloys | 100-130 |

| HRSA hastelloy | 10 - 20 |

| HRSA incoinel 625 | 10 - 20 |

| HRSA incoinel 718 | 10 - 20 |

| HRSA nimonic | 10 - 20 |

| Titanium | 20-30 |

| Titanium alloys | 20-30 |

| Ø | ae=0.15Ø | ae=0.10Ø |

|---|---|---|

| 2 | 0.005 | 0.005 |

| 2.5 | 0.006 | 0.006 |

| 3 | 0.008 | 0.008 |

| 4 | 0.012 | 0.012 |

Türkçe

Türkçe